FreshFocus Produce Items

Overview

Companies operating in the food supply chain deal with diverse inventory types. The following table provides an overview of the various inventory classifications that might apply.

| Item Classification | Description | Produce Item |

|---|---|---|

| Raw Produce | The foundational materials used at the beginning of the production process. For instance, a packing business may consider bulk products harvested directly from the field as raw materials, while for a grower, seedlings may serve as the raw material. | Yes |

| Intermediate Produce | Items derived from raw materials, identifiable for stock-taking purposes. For example, a food manufacturing company might prepare ingredients from raw materials through processes like washing and trimming before creating finished products. | Yes |

| Graded Produce | Intermediates produced from bulk raw materials through a selection or sorting process, such as size or colour grading. For instance, bulk grapes can undergo size grading to yield different intermediates for various finished product lines. | Yes |

| Packed Produce | Finished goods ready for sale. | Yes |

| Partially Packed Items | Another category of intermediate products, such as stock placed in punnets but not yet labelled. | Yes |

| Packaging Items | Packaging supplies for the product, including punnets, bags, film, labels, and more. | No |

| Distribution Packaging Items | Additional packaging items utilised in the bulk movement of individual product pieces, such as pallet corners, returnable packing lid, bases, outers, trays, pallets, film, and tray or pallet labels. | No |

Within Business Central, these classifications might be expressed with different Item Categories and/or Product Groups, or even Gen. Prod. Posting Group or Inventory Posting Group fields. However, to take advantage of extended lot information, you mark an item as a 'produce item' which enables a set of features within FreshFocus.

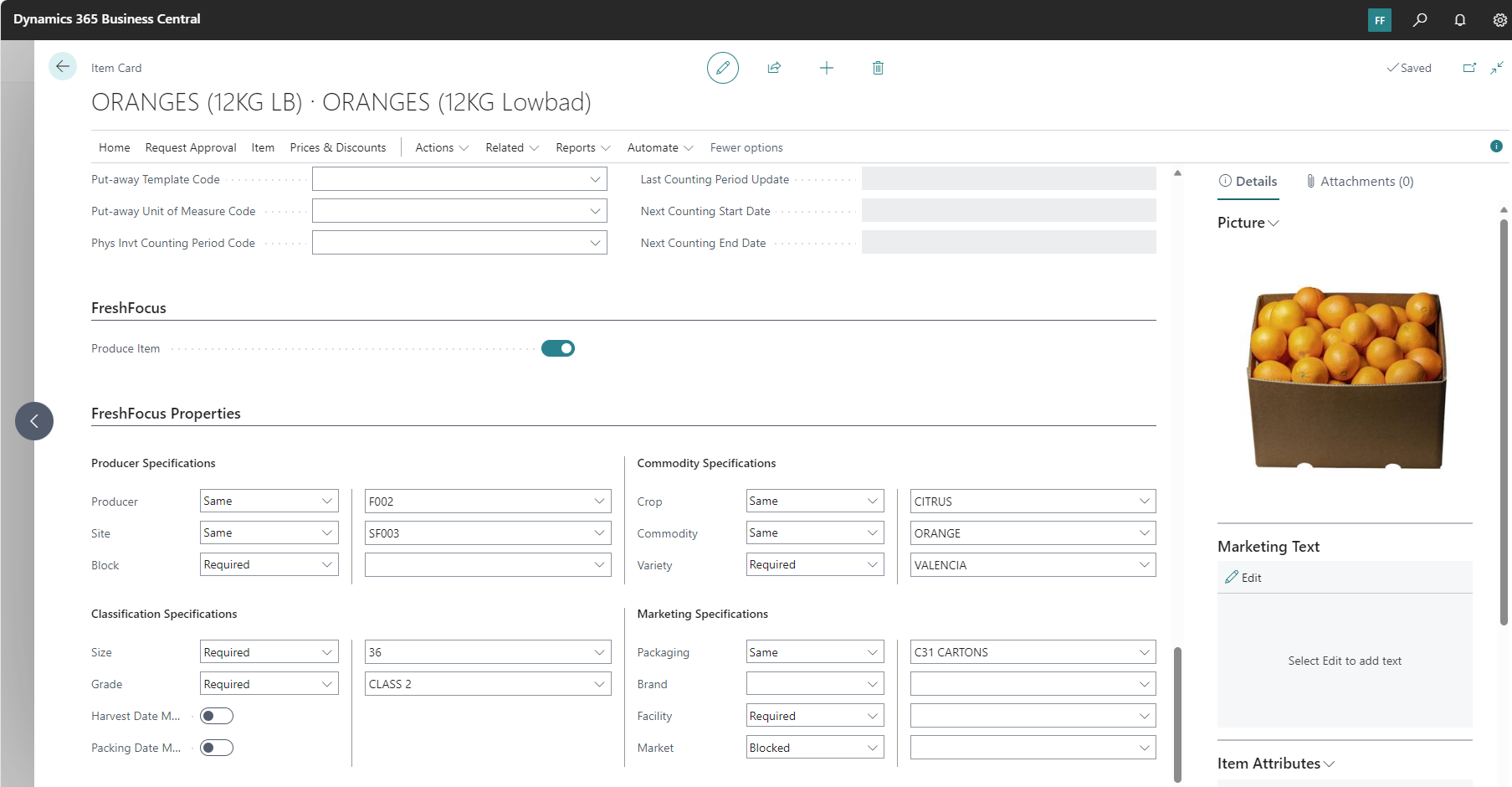

Defining Produce Items in FreshFocus

With produce properties already defined, these can be specified on any items that are marked as 'Produce Item' in Business Central.

Each property is associated with a criteria field that controls how the program sets the fields as requiring the same code, mandatory (required), restricted (blocked) or flexible (blank).

These settings affect how produce agreements, grading and packing processes operate.

Once your properties, and items are setup, you just need to ensure the following pre-conditions are met.

Tip

Properties require the following pre-condition to be used in Business Central.

-

Item Tracking Codes should be defined for the different tracking that you require, and these should be added to the produce item card. For more information see this link (External link).

-

For automatic Lot Numbering, a Number series should be assigned to the Lot Nos. field on the produce item cards.

-

FreshFocus Setup is completed.