FreshFocus Assemblies

Overview

FreshFocus provides 2 ways to 'convert' produce from one form to another and depending on the requirements you may use either or both.

- Assembly Orders: are used for scenarios where produce is simply converted. For example where previously graded produce is packed. Typical examples include re-pack orders and pre-pack orders where the inputs (and quality) are already known.

- Production Orders: can be used for simple scenarios but also support more complex arrangements including commit-to-pack; where one or more production orders are linked to a grading order, and the inputs for the packed orders are shared between various grade-out lanes.

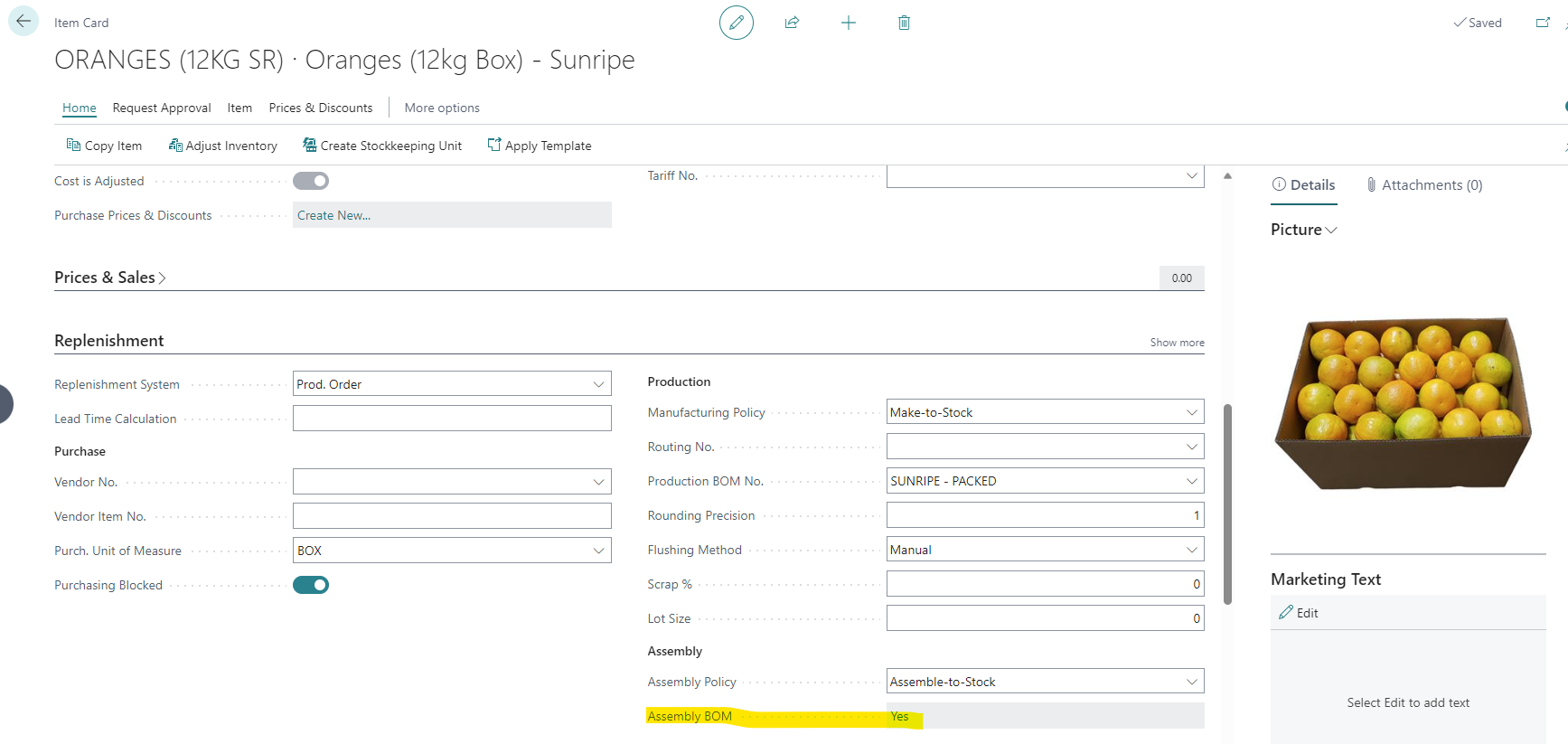

Assembly BOM

If using Assembly orders then FreshFocus utilises the assembly BOM that is defined on an item.

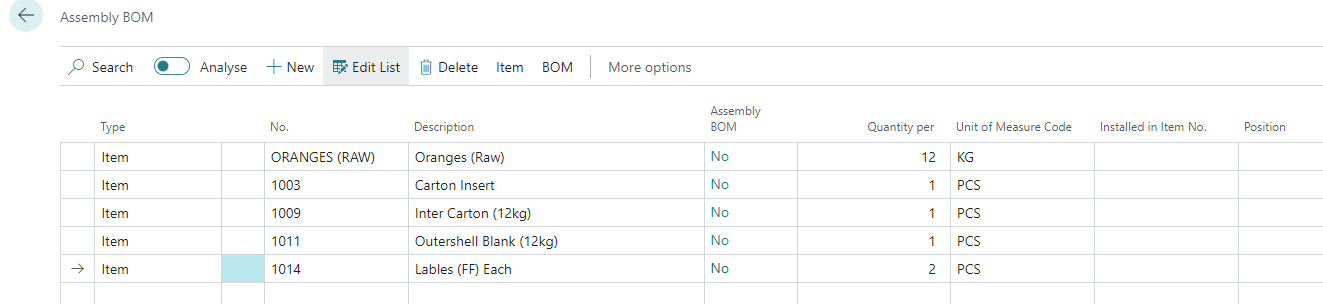

Clicking the BOM shows the items defined for use when producing assemblies for this item

The items in this context can also be assemblies themselves and not exist in stock, the assembly order can explode the component need out.

For more information refer the MS Learn content for Assembly BOMs.

Work with Assembly Orders

FreshFocus assembly functionality is based upon the standard Business Central model and process for assemblies. If you are unfamiliar with using Assemblies in Business Central, then it is recommended to first review Assembly Management in the MS Learn site.

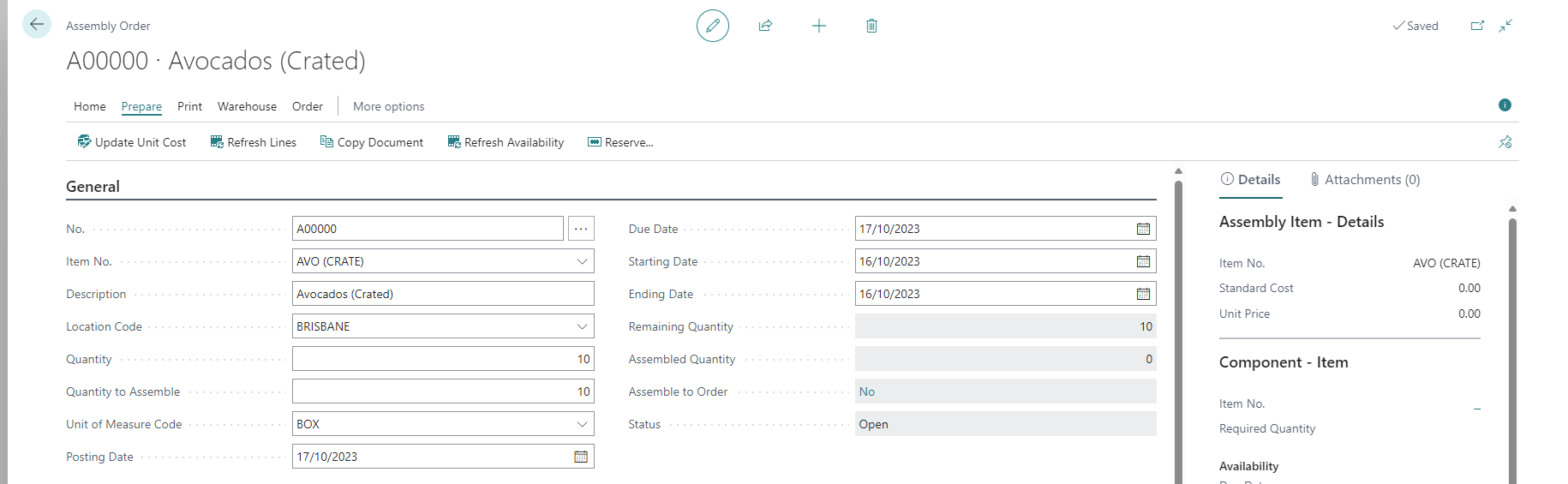

Choose the icon, enter Assembly Orders and choose the related link, or you can access Assembly Orders from the Production|Assemblies action group in the FreshFocus role center.

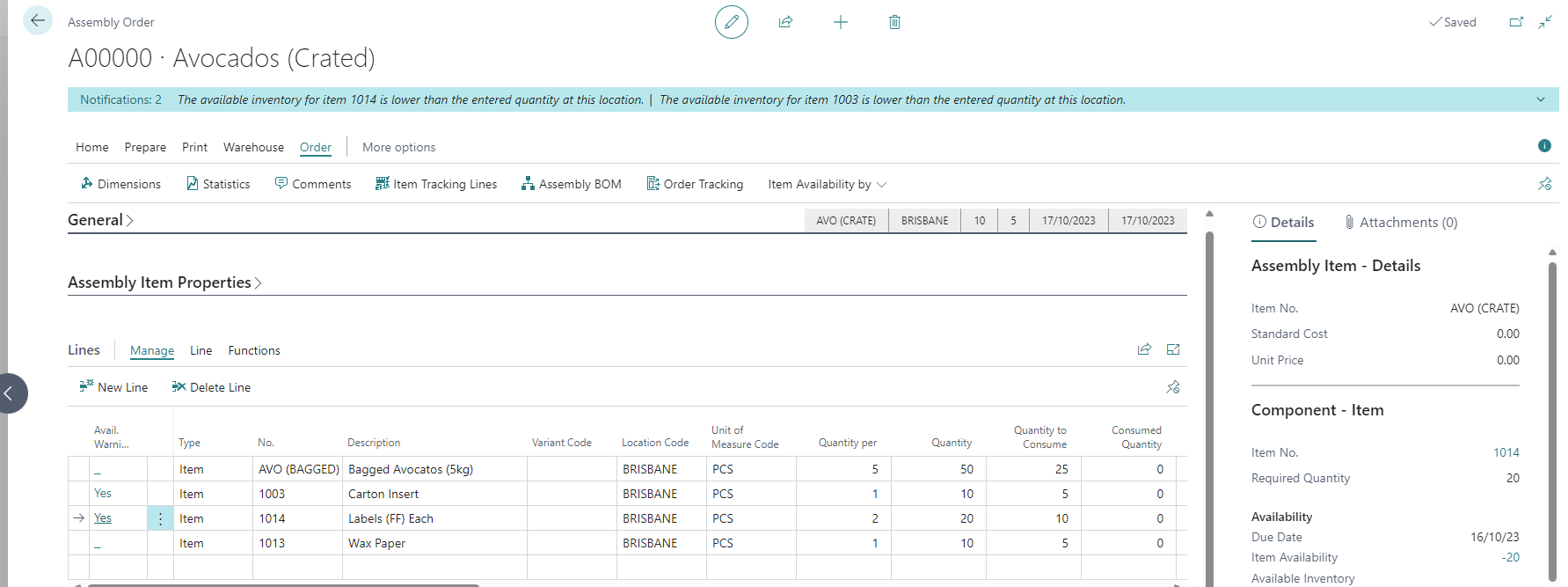

You enter the information in the header, such as Item No., Location Code, and Quantity, along with confirming the dates for the assembly.

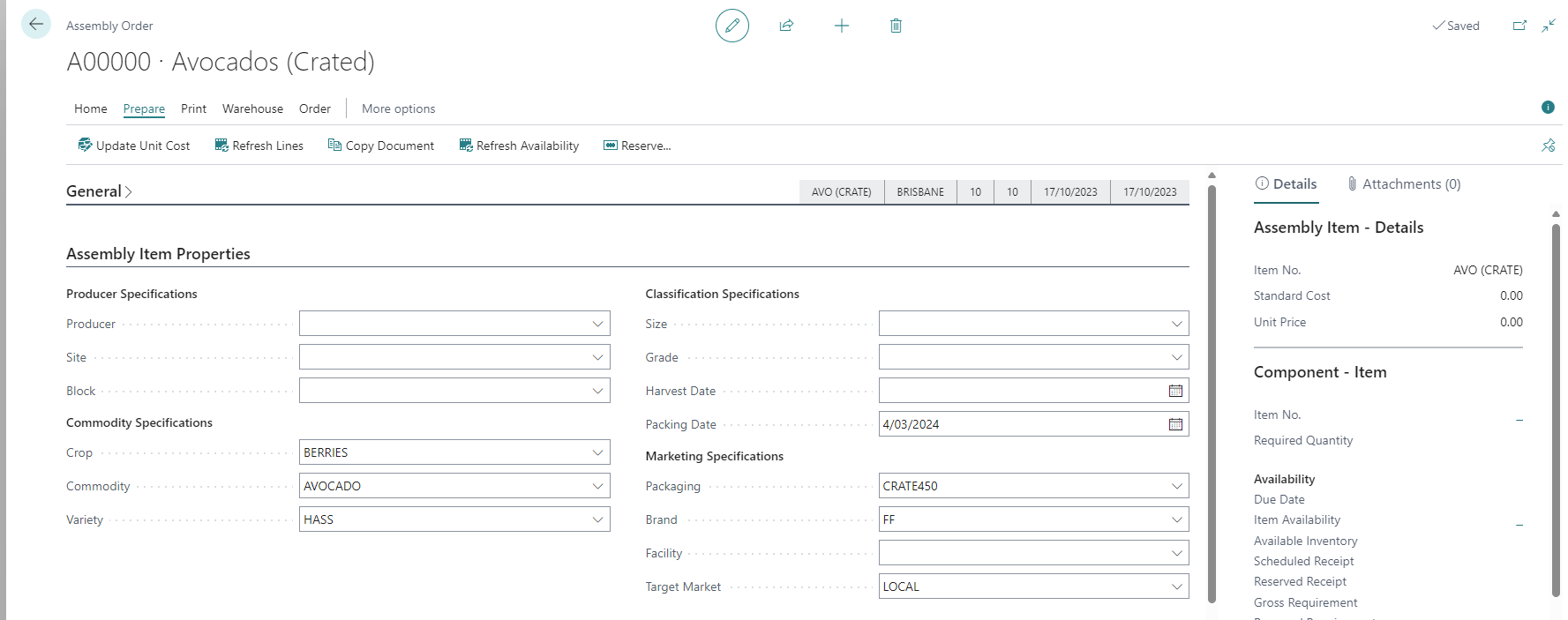

You also enter any required properties for the output item in the properties fast tab, the defaults properties are copied from the item card.

You then refresh lines function to fill-in the details from the BOM Components associated with the item. You can then fill-in any produce related criteria in the lines to restrict the available lots to use as consumption items.

Posting Assemblies

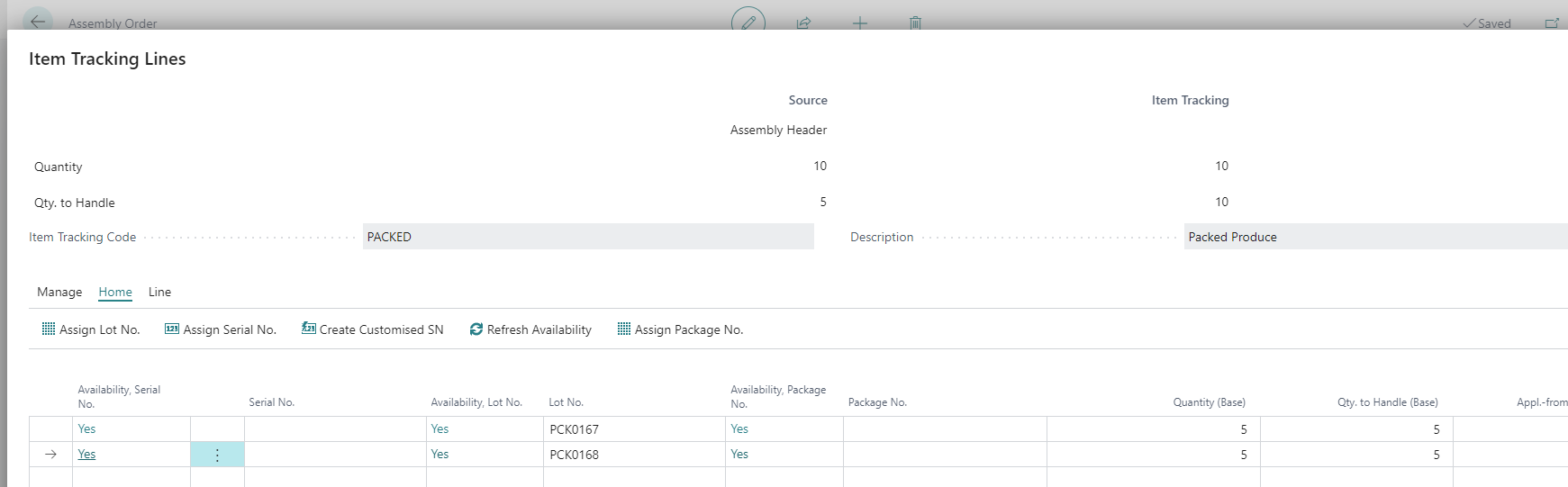

Prior to posting any assemblies you need to specify the Quantity to Assemble on the Assembly Header, and then create item tracking for both the assembly item and any produce items being consumed.

Select Order|Item Tracking Lines on the header, and enter or assign the lot number(s) to the Assembly Header.

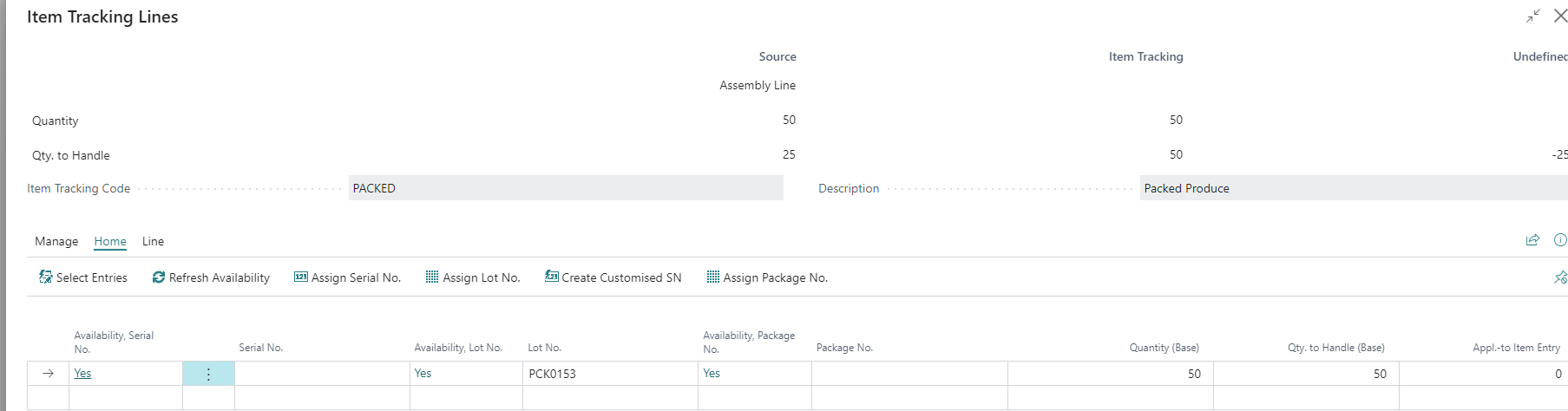

Then on the 'consumption' produce item, select Line|ItemTracking Lines, and then select from the available lots, either by using the Select Entries action, or by lookup on the tracking lines. When done select OK to return to the Assembly Order.

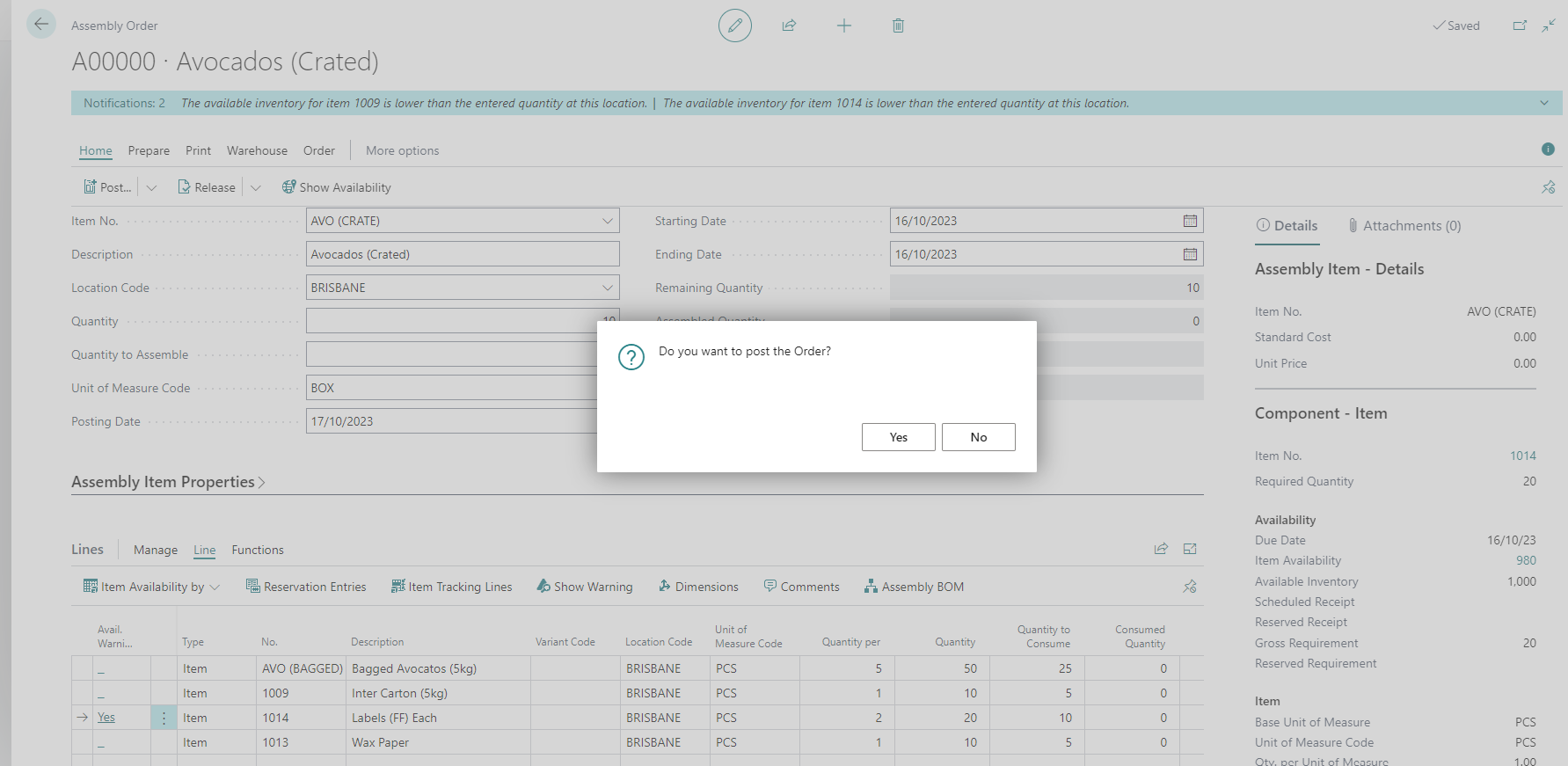

The assembly order is ready to post ,provided there are no shortages, by selecting Home|Post on the Assembly Header. Confirm you wish to proceed, and the Assembly order will be posted.

Info

Produce Tracking is created automatically if Auto Post Tracking is enabled in freshFocus Setup. Because Assemblies post output and consumption at the same time, there is no 'finish' concept at play.

Make-to-Stock vs Make-to-order

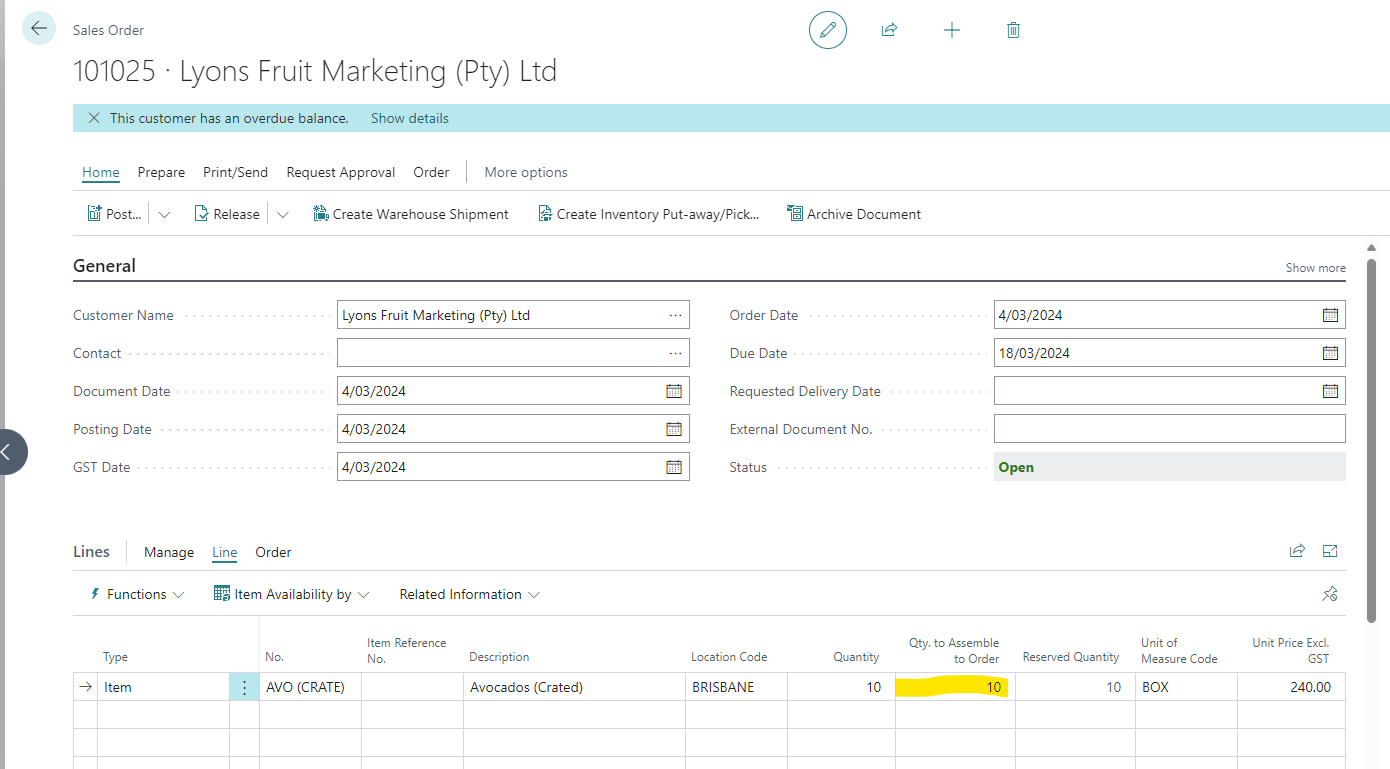

In general terms, assemblies are make-to-stock in FreshFocus. It is possible to create the assembly order from a sales order by entering the Assemble to order Quantity on the sales line, and upon posting the shipment post the assembly order as well.

However, before posting the sale, you need to navigate to the assembly order and update the properties, and assign lot numbers (item tracking) for manual consumption lines.